Split Body Ball Valves, Forged, DBB - E601

This type of valves are being especially used as line valve in Natural Gas and Crude Oil Pipelines, Pig Stations, Compressor and Measuring Stations and Pressure Regulating and Metering Stations (RMS), Pumping Stations and Loading Terminals.

When required, it can be manufactured specially for Sea Water, Waster Water, Mineral Mud (Slurry) by using suitable material in accordance to NACE Corrosion Standards.

Generally it is used between -46°C up to 100°C. It can be manufactured with various materials upon request and PSL2 level can be obtained.

Application Area

Natural Gas Pipeline

Crude Oil Pipeline

RMS

Water Works

Combined Cycle.PP

Hydrogen

Functions

ESDV - LBV - SOV - BDV - SDV - MOV - MAN - Process Valve Systems

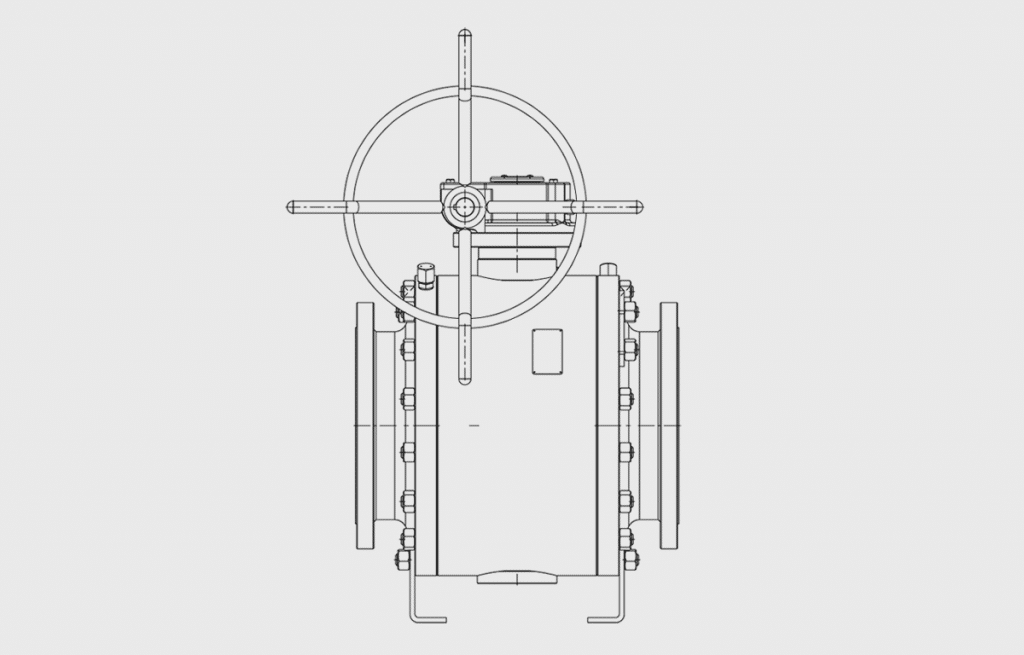

Vastas Figure E601

Type

Split Body Ball Valves, Forged, DBB

NPS

2"-56"

DN

50-1400

Class

150-2500#

Features

Two or Three Pieces Split Body (SB)

Double Block & Bleed (DBB)

Trunnion Ball (TBS)

Emergency Sealant Injection, (Stem & Seat)

Anti Static Device (ASD)

Above Ground (AG)

Full Bore (FB) or Reduced Bore (RB)

Fire Safe Design (FSD)

Body Drain & Vent

Anti blow-out stem

Standards

» Design API 6D, ISO 14313, ASME B16.34

» Face to Face size ASME B16.10, API 6D

» End Type, ASME B16.47 Series A & B & ASME B16.5

» NACE MR0175 MR0103 (optional)

» Fire safe valve design, according to API 607,

API 6FA and ISO 10497

Operators

» Lever Operated

» Gearbox (G)

» Electric Actuators (E)

» Spring Return Pneumatic Act. (GC, GL, GN, GF)

» Gas Over Oil Actuators (GO, GS, GI)