Ball Valves

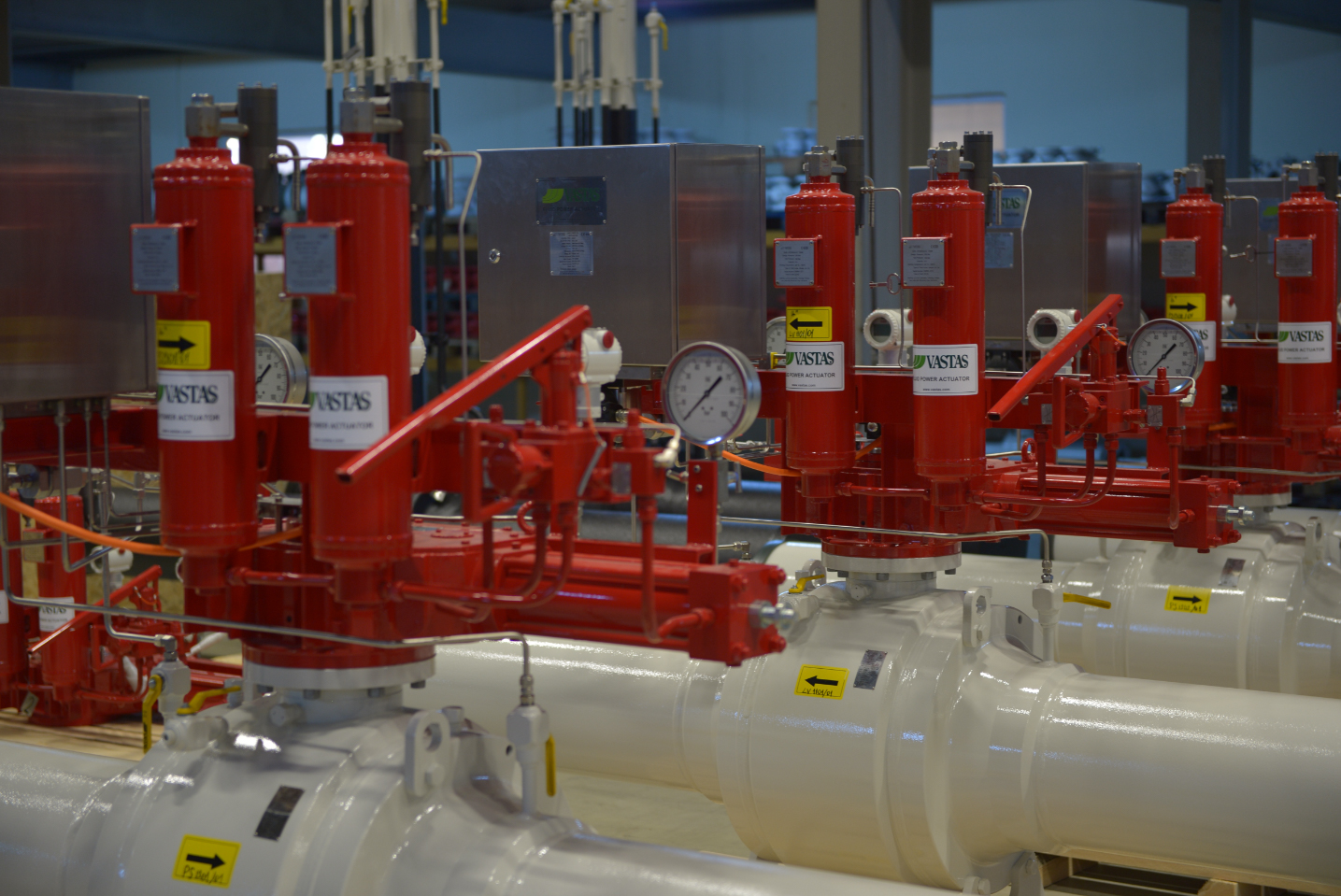

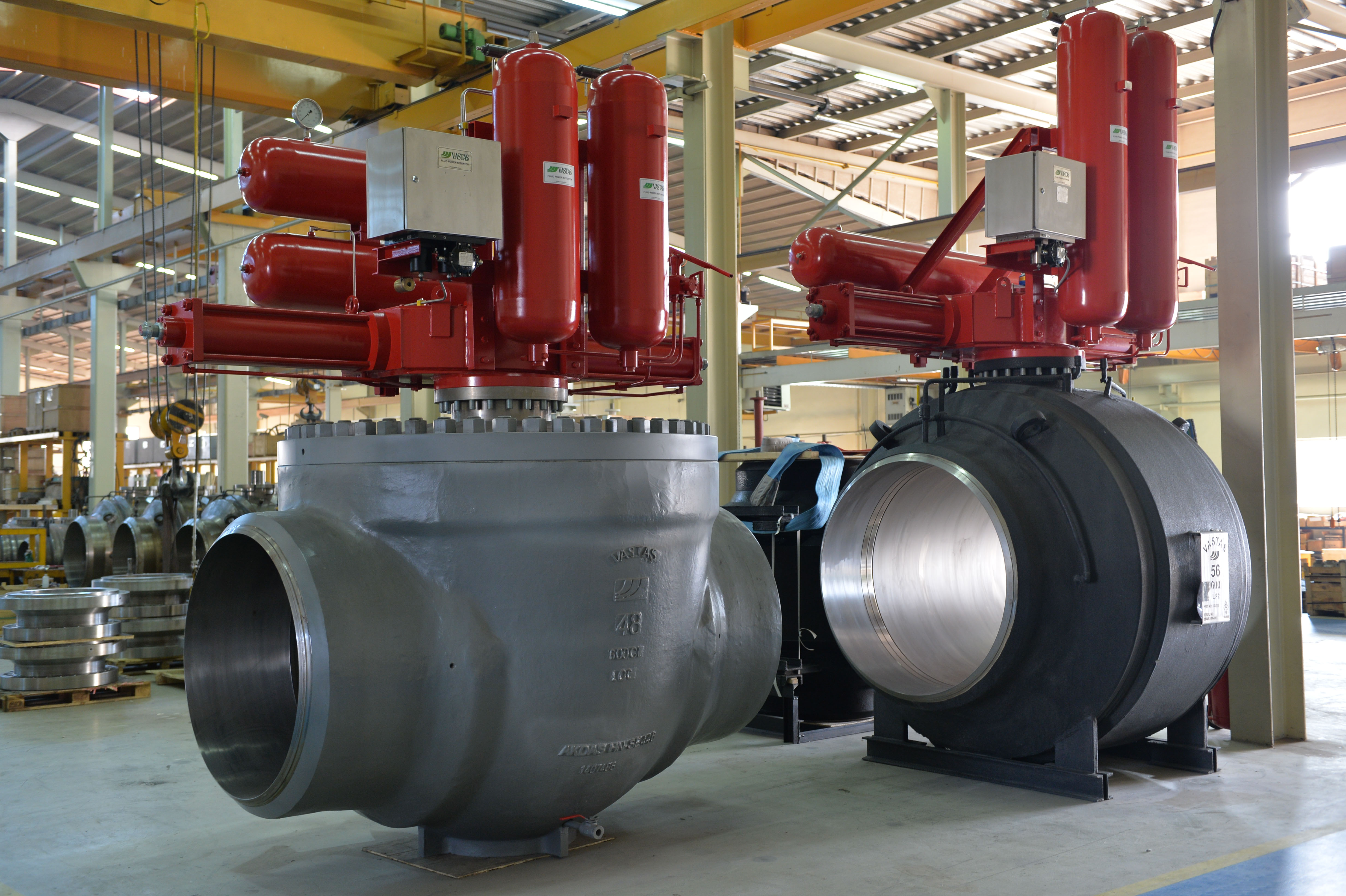

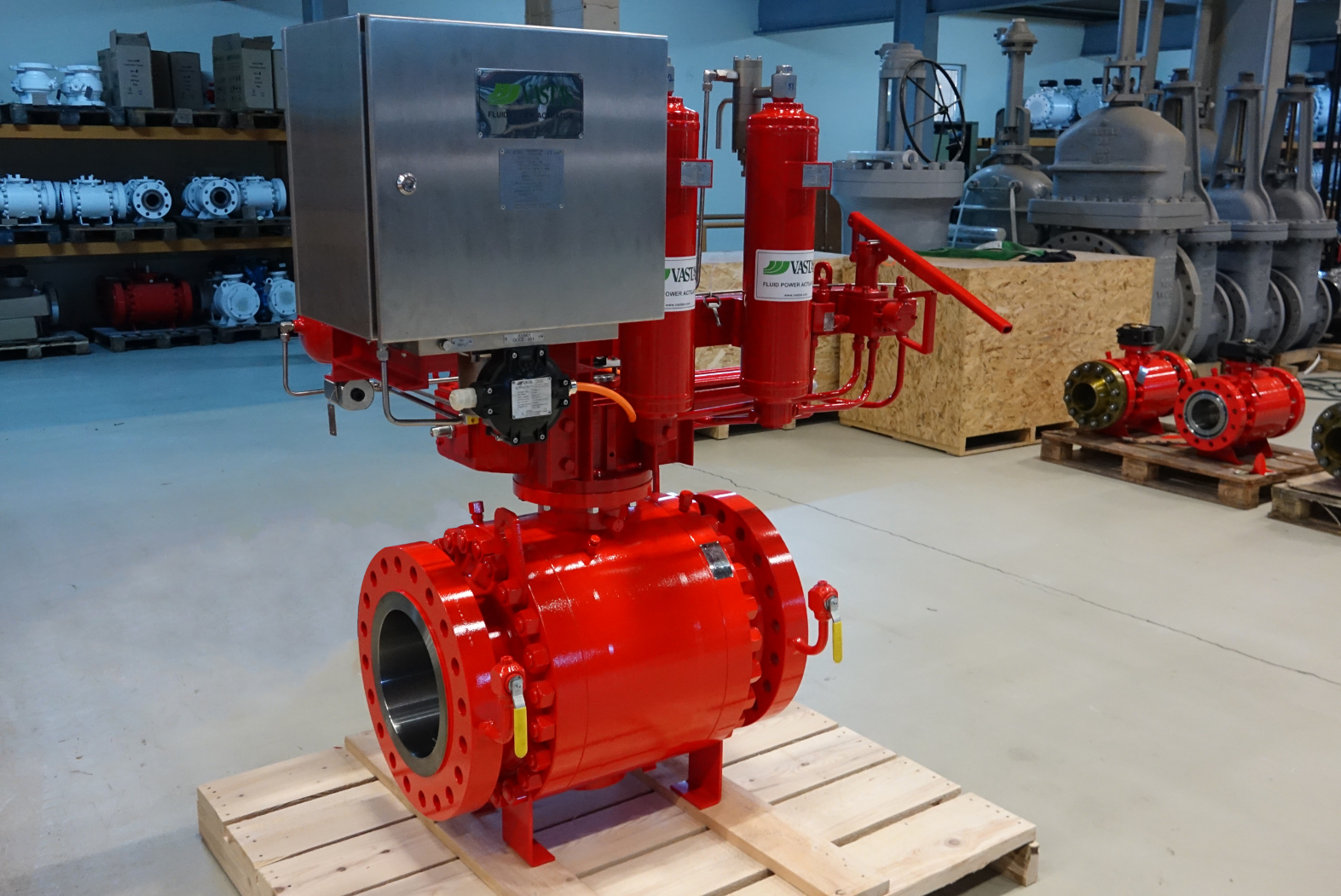

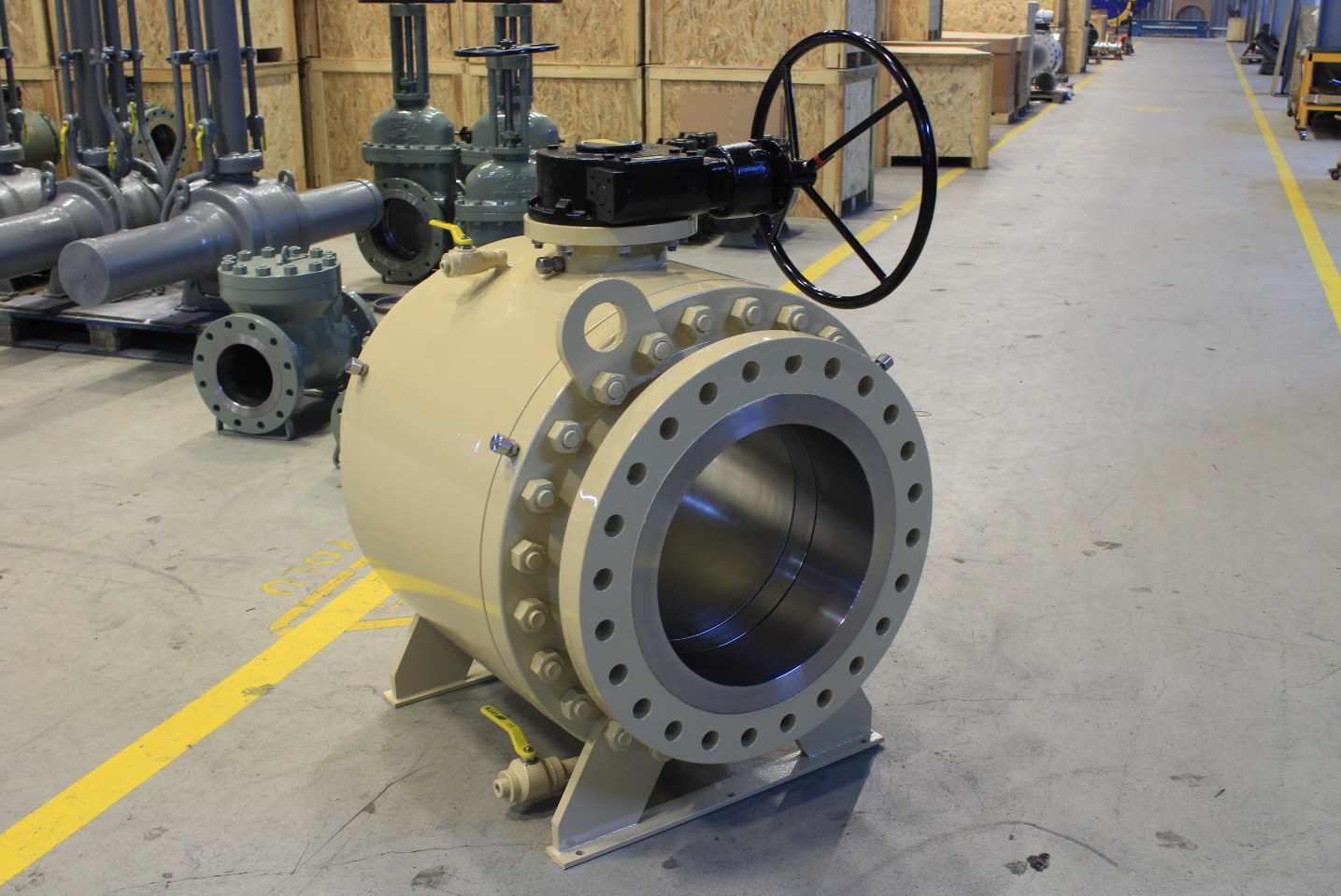

Vastas API 6D and API 6A Ball Valves are used at various onshore and offshore projects, aboveground and underground applications. They are generally used between -46°C up to 120°C.

Vastas Ball Valves are SIL (Safety Integrity Level) certified. When required it can be manufactured from special material according to NACE corrosion standards and/or temperature class. Conformity to MR0175 requirements and PSL2 Level can be obtained.