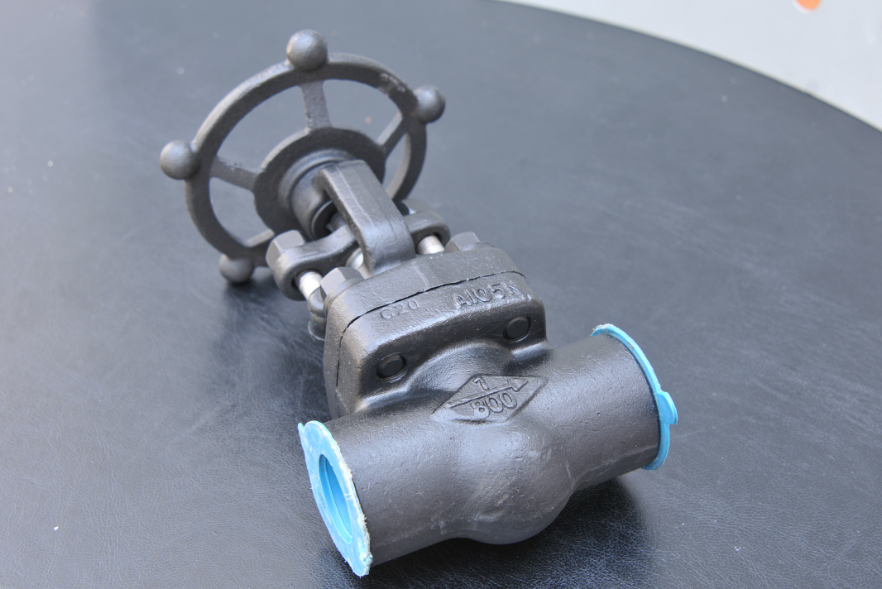

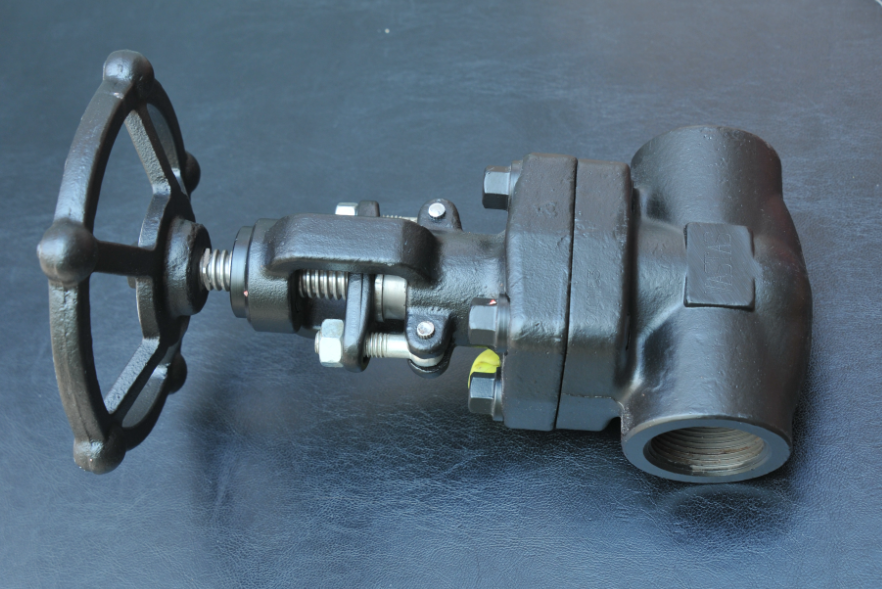

Forged Valves

These types of valves are mostly forged steel. The body of valve is constructed by welding of all parts except stem housing. No sealing elements are used which might cause leakage through.

Vastas Valves are produced with steel body and stainless trim (API Trim no 8 as standard). End fittings are designed as NPT according to ASME B1.20.1. According to customer request Vastas valves can be produced with butt welded end according to ASME B16.25 or with socket welded end according to ASME B16.11 with flanged ends according to ASME B16.5. In this case FTF Dimension is complying with ASME B16.10 standard. When required it can be manufactured from special material according to NACE corrosion standards and/or temperature class.